The drive for automotive innovation

Automotive & Transportation

Innovative automotive solutions

As the automotive and transportation industries continue their journey towards a smarter and brighter future, we see metal powder technology at the forefront of this progressive era.

Höganäs is building strong partnerships with automotive manufacturers, not only providing premium metal powder, but also fulfilling a range of application requirements. Our solutions enhance performance, and support electrification.

Cost-efficient powder metallurgy for a growing variety of pressed and sintered vehicle parts remains at the heart of what we do. But Höganäs is also pioneering metal powder for additive manufacturing in this sector, developing functional prototypes and spare components.

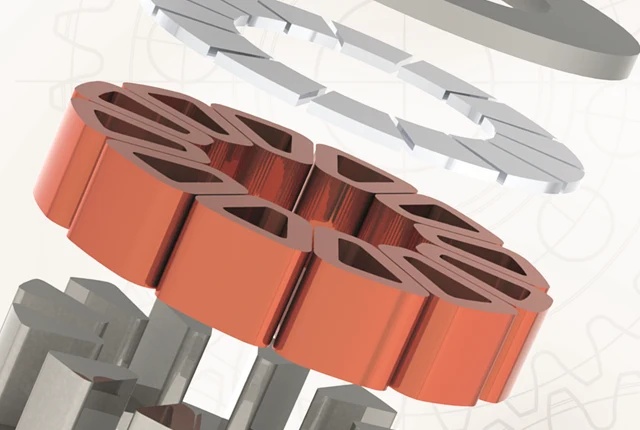

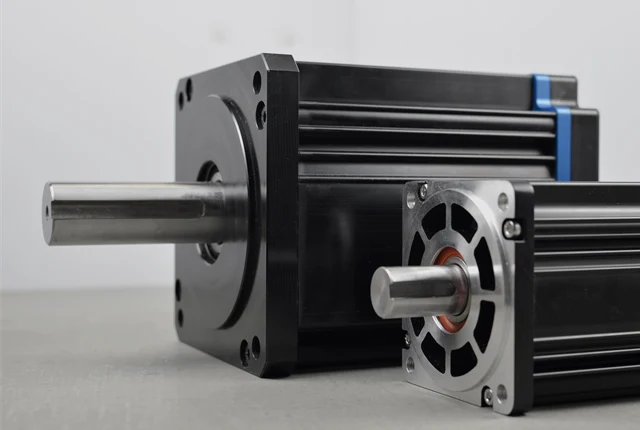

We are the market leader for high temperature brazing, offering premium pastes and in-depth expertise in joining techniques and possibilities. Moreover, our inductor, electric motor and drivetrain solutions – created with premium soft magnetic composite powders – provide flexible, more compact electronic design opportunities, helping to meet the increasing demand for smaller electric and hybrid motors.

Our ambition is to grow the range of applications that can benefit from metal powder technology, opening up a new world of opportunities for a more cost-efficient and sustainable future in automotive and transportation manufacturing.

Our main areas of expertise

- Know-how and experience of the automotive industry, its challenges, application requirements and production processes.

- Customised metal powder for electro-magnetic and friction applications, pressing & sintering, brazing, thermal surface coating, 3D printing and inductor solutions.

- Pioneering and sustainable solutions to help meet the demand for electrification, hybridisation, lower scrap rates and reduced carbon emissions.

- Close customer partnerships from conception to application, with fast time-to-market objectives.

Automotive applications

The automotive industry is a driver for material innovation and its applications of metal powders are growing day by day.

Securing lighter weight, superior performance and enhanced durability, our solutions can be used in everything from small parts to larger components with more complicated shapes. Combining cost-efficiency and innovation, they also help support automotive electrification.

Imagine a total metal powder car

Sintered components are already widely used in modern transmission and engine systems. But metal powders are also ideal for techniques such as brazing, thermal surfacing and additive manufacturing.

With our soft magnetic composites solutions we will help you meet the increasing demand for cost-efficient electromagnetic applications in electric vehicles and hybrid cars.

Soft Magnetic Composites in Electric motors

Electric motors impact almost every aspect of modern society. They are used in most industrial processes and at some point in the manufacturing of nearly every conceivable product that is produced in a modern factory. Hair dryers, fans, air conditioners, refrigerators and freezers, vacuum cleaners and food blenders, and a multitude of other appliances we use in our daily lives all use electric motors to convert electrical energy to mechanical energy.

The electric motor is now also rapidly being established as the foundation of future transportation in hybrid and battery electric cars, and furthermore as electric drive source of former mechanical auxiliary systems such as pumps and A/C compressors.

The advantage of helical gears in PM

Helical gears are used in geared applications that require higher contact ratio for noise and stress reduction. Using PM technology, helical angles of up to 36 degrees have been achieved in series production. Very advanced gear body geometries can be designed and net or near net shape compacted. This enables weight reduction as well as addition of other features such as splines, part number identification, design for assembly features etc.

All of this is achieved without any machining. PM, a considered green technology, thus opens up opportunities to lower the per unit cost and to add value.

Get inspired

Making powder technology first choice

A key to successful product development and industrialisation is the intimate work with material, process and design. Höganäs can realise this by opening up for close collaborations in the Customer Development Centre.

Metal powders contribute to sustainable development

Metal powder technology provides endless opportunities; not only does it enable our customers to reduce their material and energy consumption, but it also helps them use new and better techniques that make final products more efficient and less expensive.

We believe that the inherent power of metal powders can be utilised to a much larger extent than it is today. We are also convinced that metal powders can contribute to sustainable development. With metal powder solutions, we can contribute to solving many of society’s pressing challenges, such as resource scarcity and the need for renewable energy.